In Electrical installation,Grounding or Earthing is the important thing that we need to highlight during discussion and execution of the electrical installation.Its to ensure the equipment or installation is protected by good grounding system.

The grounding installation method must be followed and guide by proper CBA (Current Best Approach) that can provide us the best technique for electrical installation grounding.Please refer your Local Electrical Guideline or Code and Standard Pertaining to Bonding and Grounding system from IEEE,NEC or NFPA 99.

This time I want to share some information about grounding requirement that I’d used for reference when performed electrical installation project.I hope this information can give some idea and guide line about grounding for installation.

Grounding Requirement

1) The 24 VDC systems shall be grounded at the negative terminal of the power supply only. Exception is only when an internally grounded power supply is used or when the system is designed to be floating. (this shall be brought to the Electrical Engineers attention)

2) The common (neutral) on the control transformer secondary shall be grounded to the control panel/ enclosure.

3) No separate earth stakes for instrumentation/computer systems will be used. Where a “clean” ground is required as part of the vendor requirement a dedicated earth wire connected directly to the power supply earth may be used.

4) Each electrical device, machine/ process skid base, metal enclosure, door, support or steel structure shall be properly grounded/ bonded to a common earth ground point.

5) All ground wires shall be run inside conduit or integral to cable.

6) A individual grounding conductor minimum 1.25mm2 (or #14AWG) shall be provided for each cable (either a separate conductor or integral with the cable) installed in a conduit, flexible conduit or trunk system.

7) Impedance measuring device shall be used to verify that the measured impedance between any touchable grounded points on the machine and the main power systems ground point is less than 0.1 ohms. Note: This shall be tested by injecting 10 amps into the circuit derived from a SELV (safe electrical low voltage source and measuring the impedance between the equipment ground (PE) terminal and relevant points that are part of the equipment grounding.

8) Bolted ground connections should be made with compression type ring lugs complete with non-corrosive hardware and lock-washer.Under no circumstances shall rigid/flexible conduit or wireway be used in lieu of a ground.

PE GROUND CONNECTIONS SHALL:

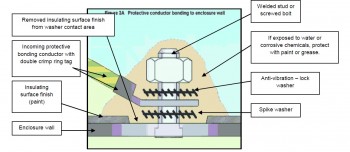

1) Use toothed star washers for safety bonding under a ring-lug or other device to be grounded. Ring lugs must be double crimped.

2) Use a locking type fastener to hold it in place. Fasteners with integral washers may be used if they have external tooth stars.

3) Only one ground wire per grounding terminal shall be permitted.

4) All star washers shall be steel (not copper, brass or bronze).

5) Non-conductive coatings such as paint and anodize shall be removed in the area of the star washers.

6) Primary PE ground wire shall be the same size or larger than the voltage carrying wires.

7) PE ground wires from the primary PE ground wire may be wired in series (i.e. daisy chained) and branch circuits may have reduced size wire, but must be able to carry the maximum fault current for the devices being grounded.

8) The primary PE ground connection shall be a single dedicated conductor on a terminal and/or stud with a direct connection to the main chassis or sub-panel and a dedicated locking fastener.

9) Main incoming ground from the plant to the panel shall be labeled with the PE ground symbol and be separately terminated.

10) All grounded connections not identified by green and yellow on the conductors shall be identified with the PE ground symbol.

Lemau,

I have always followed the PE type connection as you described above. Now I have a customer that wants to see the exact UL / CE requirement that spells this out. I have tried many searches on the internet with no luck.

Hi Robert,

The grounding installation method must be followed and guide by proper CBA (Current Best Approach) that can provide us the best technique for electrical installation grounding.Please refer your Local Electrical Guideline or Code and Standard Pertaining to Bonding and Grounding system from IEEE,NEC or NFPA 99.

Is it really necessary to paint or grease the finished installation. We use varnish which adds 10mins and more to assembly including drying.

You are correct need grease paint for smooth installations